Like any manufacturer of high-precision parts, Manth Brownell faces its share of production challenges. About five years ago, however, the company addressed a problem that had nothing to do with tight tolerances, complex geometries or other dimensional issues. Rather, parts were being rejected based on cosmetic concerns resulting from insufficient cleaning. In addition to improving the reliability of the company’s parts-cleaning process, replacing aqueous systems with Compact 80C solvent-based systems from Dürr Ecoclean (Plymouth, Michigan) has reduced energy, waste removal and labor costs.

Like any manufacturer of high-precision parts, Manth Brownell faces its share of production challenges. About five years ago, however, the company addressed a problem that had nothing to do with tight tolerances, complex geometries or other dimensional issues. Rather, parts were being rejected based on cosmetic concerns resulting from insufficient cleaning. In addition to improving the reliability of the company’s parts-cleaning process, replacing aqueous systems with Compact 80C solvent-based systems from Dürr Ecoclean (Plymouth, Michigan) has reduced energy, waste removal and labor costs.

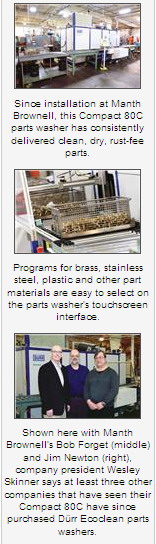

Based near Syracuse in central New York, Manth Brownell was founded in a garage in 1951. Today, the contract manufacturer serves industries including automotive, utilities, fluid power, appliances and more from two plants totaling 135,000 square feet of manufacturing and office space. While it specializes in precision-turned parts, the company’s lineup of nearly 160 machines also includes milling capability. Materials machined here include brass, steel, stainless steel, nylon, plastic and more.

By the time the company moved to re-evaluate its parts cleaning operations, it had experienced numerous difficulties with the aqueous systems already in place. These systems were ineffective for removing chips from the internal surfaces of threaded, blind holes when oil from the machining process collected there. Additionally, the wash’s non-neutral pH caused spotting in some materials, which could potentially impede downstream brazing and soldering processes. Attempts to bring the pH level closer to neutral by reducing the amount of soap often caused brown spotting from leftover oil that had dried on the part. Finally, with no vacuum in place for chip removal, chips tended to accumulate at the bottom of the wash chamber only to be churned up and contaminate other parts during later cycles.

The company also sought to address broader issues with the aqueous systems, including their high energy costs, excessive water waste and long wash times. All of these problems led it to consider solvent-based replacements, particularly models with a vapor degrease option. Engineers researched various systems before deciding that Dürr Ecoclean’s Compact 80C offered the right combination of performance, energy efficiency and ease of use.

This system’s cleaning media consists of non-halogenated carbons, which are said to enable the safe and economical use of solvents for removing oils, greases, emulsions and swarf between or after manufacturing processes. Different process variants use hot and/or cold immersion with down-line vapor degreasing. Additionally, the system is environmentally friendly because the cleaning and drying processes take place in a vacuum work chamber. This saves heating energy and minimizes vapor loss to prevent problems with emissions or excessive humidity in the shop.

Heat recovery throughout the entire process further reduces energy use. The system uses a distillation process to separate solvent from the cutting oil for reclamation before returning it to the wash tank. This ensures that parts are cleaned only with pure solvent. Manth Brownell reuses the reclaimed cutting oil for machining after filtering and replenishing it with the necessary additives. Since implementation, problems with improperly cleaned blind holes, spotting and chip recirculation have been eliminated. In fact, the company says that not a single customer has rejected a part for cleanliness specifications, and another machine shop has since contracted with the company to wash a hydraulic automobile transmission component. “They’re paying us just to wash their parts because we have the equipment that meets the ISO standard,” says Jim Newton, environmental and safety compliance engineer at Manth Brownell.

A single Compact 80C not only uses less energy than the aqueous models it replaced, but also does twice the work of those systems. The company notes that drying alone could take as long as 20 minutes on the aqueous systems, whereas the longest total wash it has programmed on the new unit takes only 10 minutes, including vacuum drying.

In addition to speeding the cleaning process and cutting back on energy use, the system has reduced labor costs and waste. The aqueous units required Mr. Newton to check and alter the chemistry of the wash every day and empty as much as 1,200 gallons from the wash chamber every month. Since installing the new system, his maintenance workload has been greatly reduced. Moreover, with an optional, automatic loading system, the Compact 80C can be run by one operator. This further reduces labor costs compared to the previous system, which required two.

The company adds that the unit’s intuitive control panel simplifies operation and new employee training. By simply selecting the appropriate wash program from icons on the screen, users can initiate a range of diverse cleaning cycles without extensive knowledge of the system or the process. For example, the program for plastic parts does not include vapor degreasing because that function generates temperatures that could distort the plastic, although a trainee might not know that. “You can easily select what you want it to do and what you don’t want it to do. The wash operator only has to read the ‘recipe card’ that tells which program to run and which basket will receive the parts,” Mr. Newton says.

Manth Brownell was satisfied enough with the first Compact 80C to add a second unit two years later in a nearby facility for redundancy and better product flow. The older system serves more than 100 machines, while the newer services about 60. Both run 16 hours a day over two shifts. While both of these systems are the same basic model, the newer one features an ultrasonic cleaning option. Judging from Manth Brownell’s experience, Mr. Newton says it is clear that Dürr Ecoclean works to constantly improve its machines, their hydraulic layout and their electrical components.