Scanning of a C-130 Cargo Bay Completed in Less Than an Hour

When your mission is to collect information to assist with life threatening situations, there is no room for mistakes. This need for accuracy led researchers at the West Virginia University Research Corp. and the National Guard to ShipShaper, LLP, an engineering service provider from Morgantown, WV.

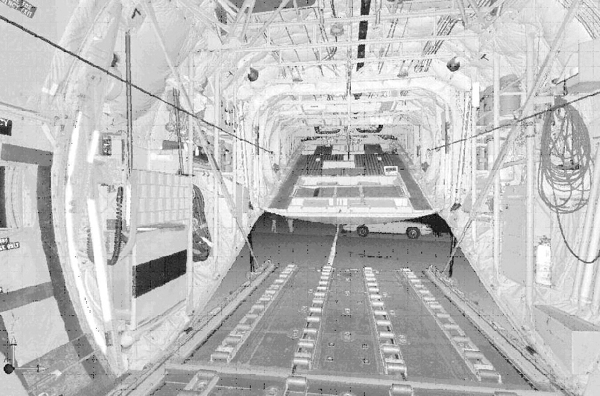

ShipShaper’s mission was to determine the dimensions of a C-130 cargo bay that would serve as the host for the Oculus System - a sensor deployment system used for a variety of applications, including reconnaissance data collection, data communication to ground stations and to serve as an aerial command and control center for search and rescue disaster operations.

ShipShaper’s mission was to determine the dimensions of a C-130 cargo bay that would serve as the host for the Oculus System - a sensor deployment system used for a variety of applications, including reconnaissance data collection, data communication to ground stations and to serve as an aerial command and control center for search and rescue disaster operations.

ShipShaper faced two challenges. The position of the Oculus System was integral to its performance, therefore the cargo bay dimensions had to be accurate. With limited access to the C-130, the measurements also had to be collected within a short time frame.

Solution

With accuracy and speed in mind, ShipShaper employed laser scanning technology from FARO Technologies. FARO’s Laser Scanner LS 880 scans 120,000 points per second, generating more than 7 million points per minute, all within an accuracy of +/-3mm. Raymond Lovett, managing partner of ShipShaper, had previously used the FARO Laser Scanner LS to generate 3-D measurements of subs, destroyers and other large ships.

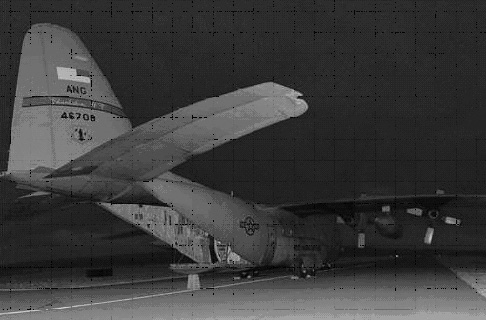

“The LS was the best type of unit for interior and 3-D measurement,” Lovett observed. “The lower resolution scans still have good accuracy and don’t take long to perform.” Crew members flew a C-130 to Hart Field in Morgantown, WV. Within an hour, Lovett generated five scans (two interior and three exterior) of the plane’s rear. Each scan was conducted at 1/5 maximum resolution, and took approximately 3 minutes to complete.

“The LS was the best type of unit for interior and 3-D measurement,” Lovett observed. “The lower resolution scans still have good accuracy and don’t take long to perform.” Crew members flew a C-130 to Hart Field in Morgantown, WV. Within an hour, Lovett generated five scans (two interior and three exterior) of the plane’s rear. Each scan was conducted at 1/5 maximum resolution, and took approximately 3 minutes to complete.

“The plane came in out of Charleston. The crew landed and had lunch while we took the scans,” Lovett said. “They came out from lunch an hour later and flew off.” Lovett emailed the scanned data to Direct Dimensions, an engineering firm out of Owings Mills, MD, who placed the data in an STL framework, using Polyworks software to complete the process for submission to the National Guard. Flight tests using the Oculus System were a success, opening the door for commercial production of the system.

Return on Investment

ShipShaper upgraded to laser scanning when the process was new to the industry. Lovett recalls his first unit functioning much slower than FARO’s LS, which is up to 100 times faster than normal time-of-flight scanners. “It used to take us six hours to perform a dozen scans,” Lovett observed. “With the FARO LS we can take a dozen scans in less than an hour.”